Cabinet Vision Design & Drafting Services

CABINET VISION is the industry leading software tool for the cabinet & joinery industry. This Software helps to enable any furniture, commercial fit-out or cabinet manufacturer to fully automate and integrate their design through to manufacturing processes.

Saves Time in Design & Set-out

Increases Turnover

Key Features of CABINET VISION SOFTWARE:

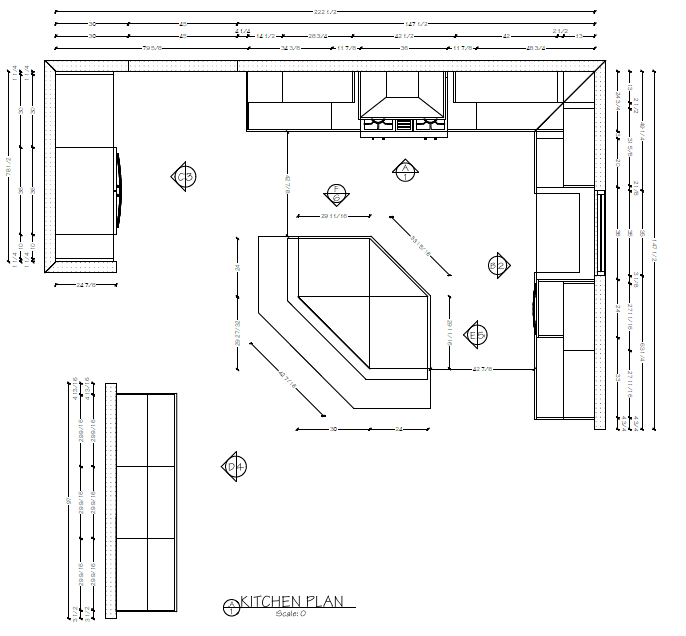

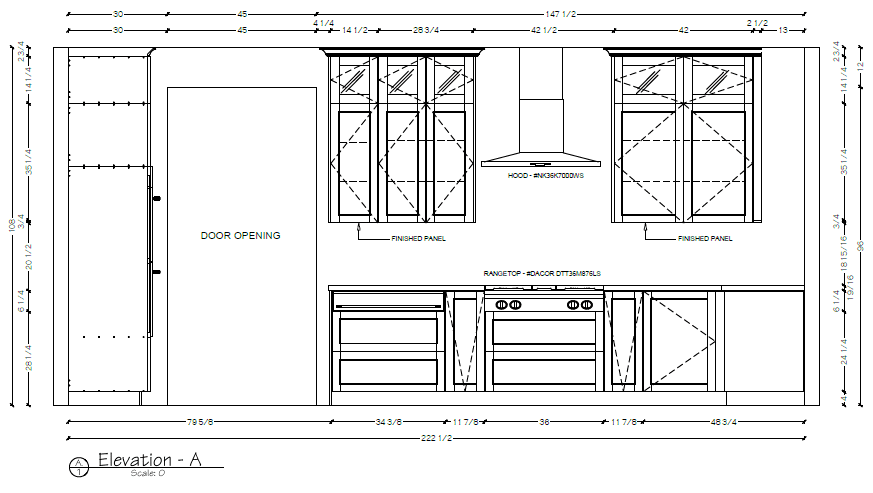

- Complete your designs with ease using plan and evaluation views

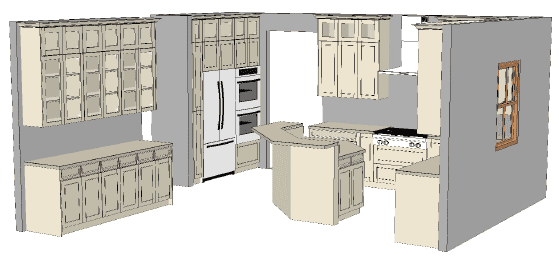

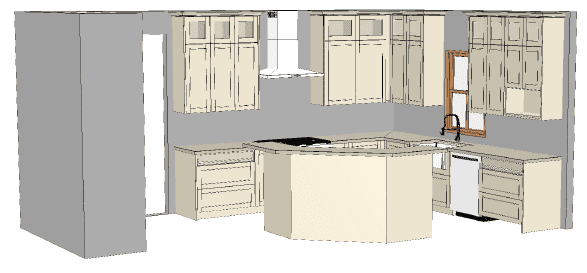

- Photo-Realistic Drawings - produce high-quality 3D renderings to help win more jobs

- Easily customize your job & build your library with cabinets.

- Cabinet Editing - Easy creation of assemblies that will allow you to quickly build your library and create one off custom cabinets.

- Generate Cut lists

- Produce 'Material Summary' Reports to be able to provide how much board, edging & hardware you will need.

- With Bid Centre, improve your businesses quoting and manage your pricing more effectively

- Seamlessly connect Cabinet Vision with your CNC Machine, meaning you can start and finish the job all in the one program